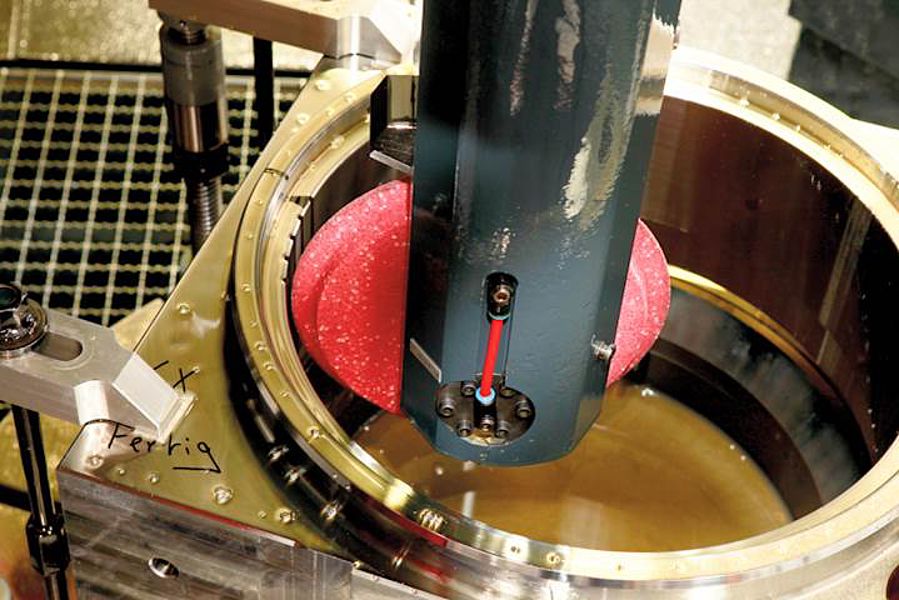

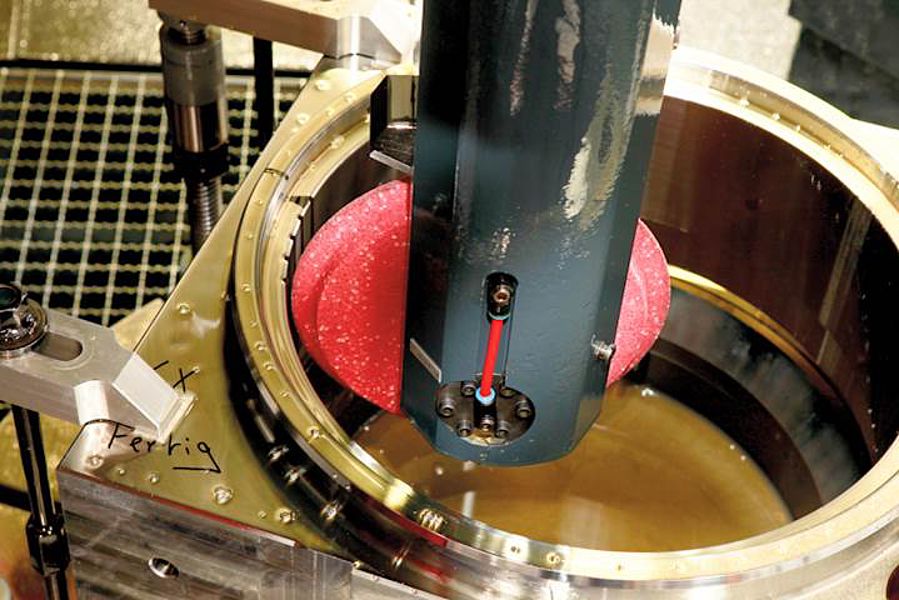

Ceramic grinding tools

High grain retention forces, definable chip clearance for ultimate removal rates and cool grinding – ceramic grinding tools are developed in-house by THELEICO and represent its expertise.

Manufacturing process

- After mixing and moulding, fired at temperatures of 1,000 to 1,400 °C

- Finished according to customer requirements

- 90 years of experience in the production of ceramic grinding tools

- Tested under internationally recognised safety standards

- All products are guaranteed to be made without using napthalene

Properties

- High grain retention forces / long service life

- High temperature stability (wet grinding predominantly used)

- Good profiling and dressing capacity

- Possible to produce highly porous grinding tools with defined chip clearance

- Unlimited shelf life

- Highest resistance to cooling lubricants

Delivery range

- Diameter: from 50 to 1,100 mm

- Width: up to 600 mm

- Grinding discs for face grinding in compact or perforated design, can be screwed or glued onto support plate

- In all shapes according to ISO / EN standards or drawings

- Cutting speeds up to 100 m/s

- Sintered, normal, high purity and monocrystalline aluminium oxide, silicon carbide